Process

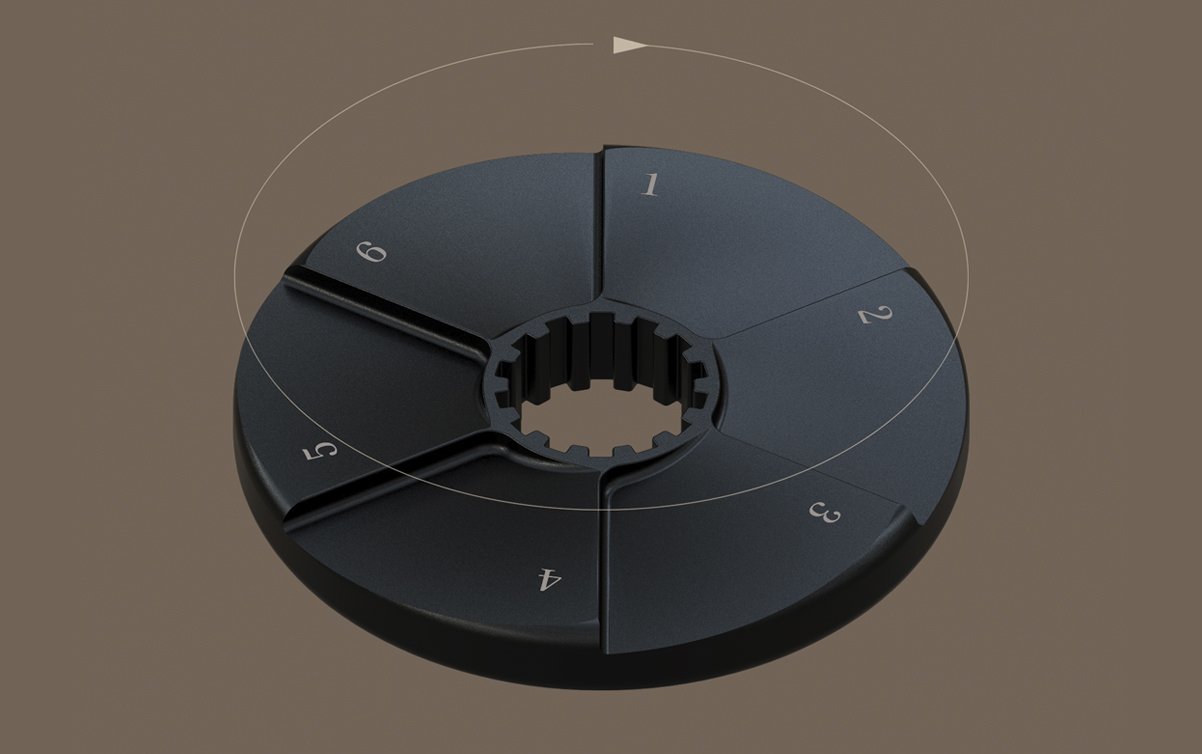

Stages in the quality process:

- Needs assessment:

Discussion with the client. Discussion with the client. - Preliminary design:

Ideate alternative solutions to arrive at a design and cost that is satisfactory to the Client. Includes discussion, rough modelling, layout design. Modelling of any existing products or equipment, environment by measurement or from old drawings. - Design:

SolidWorks 3D software. Modelling, material selection, mechanical solutions, strength calculation, motion analysis. - Prototyping:

If necessary, fabrication of a prototype model of the device or part of the device to verify the durability, functionality, etc. of the structure. Manufacturing of parts by 3D printing, machining, etc. - Documentation:

Producing the necessary documentation of the product or device for manufacturing. If necessary, we also provide operating and maintenance instructions. - Production:

Manufacturing of the product or device. We can also assist the customer in finding the right supplier for parts or assemblies.

The Leanmec quality process is a tailored service

We offer people-to-people product development, with open discussion.

Our years of experience and cooperation with our customers ensure quality and the achievement of objectives in a cost-effective and timely manner.

Our customers appreciate getting exactly the service they need, and we want to be the best at it. Our process can cover everything from needs assessment to equipment manufacture and maintenance, or just the preparation of product manufacturing drawings.